Increased competitiveness

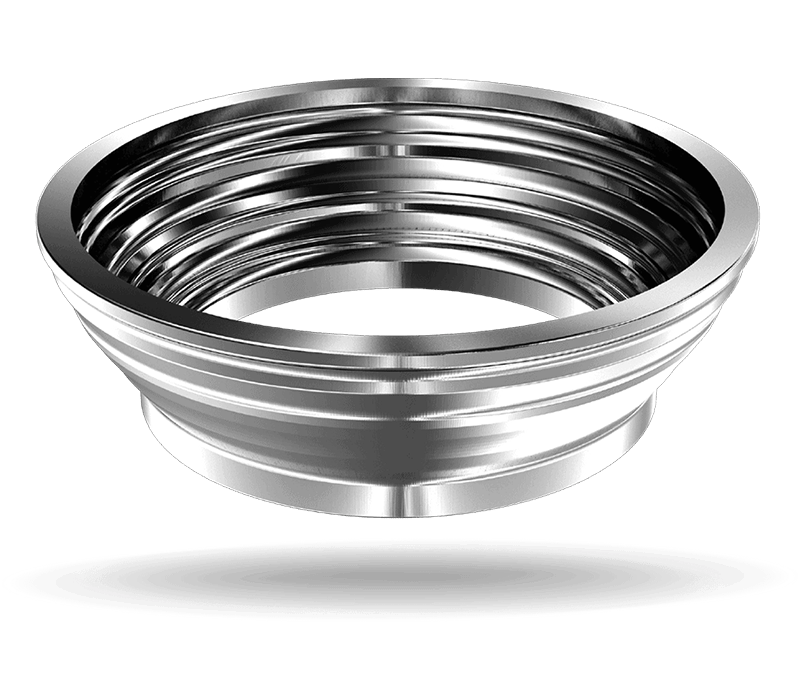

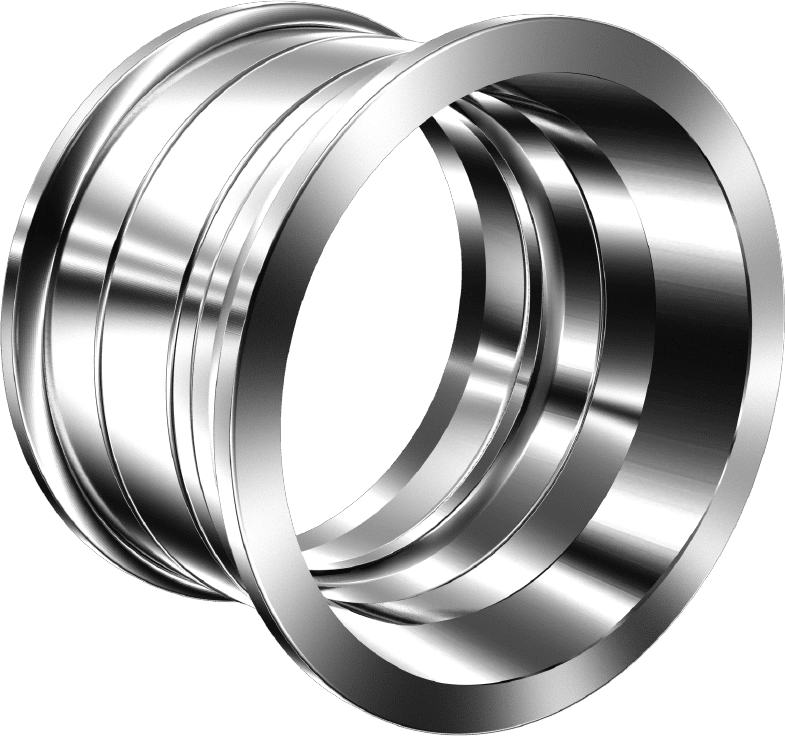

This ring forging process offers significant savings on material and machining hours, plus grain flow direction to the final shape. Contoured and near-net-shape rolled rings have both technical and economic benefits while meeting their unique geometries.

MATERIAL |

RANGENear-net shapes are forged with special tools to match the customers’ drawings. |

BENEFITS

-

Near-net-shape rings bring significant cost savings on the input weight of raw material.

-

Switching from castings to contoured rolled rings will result in an improved and consistently higher quality product.

-

At FRISA, we have a vast experience producing contoured rings in any size and material grade and can recommend the best solution for you.